INSTALLATION VIDEOS

About

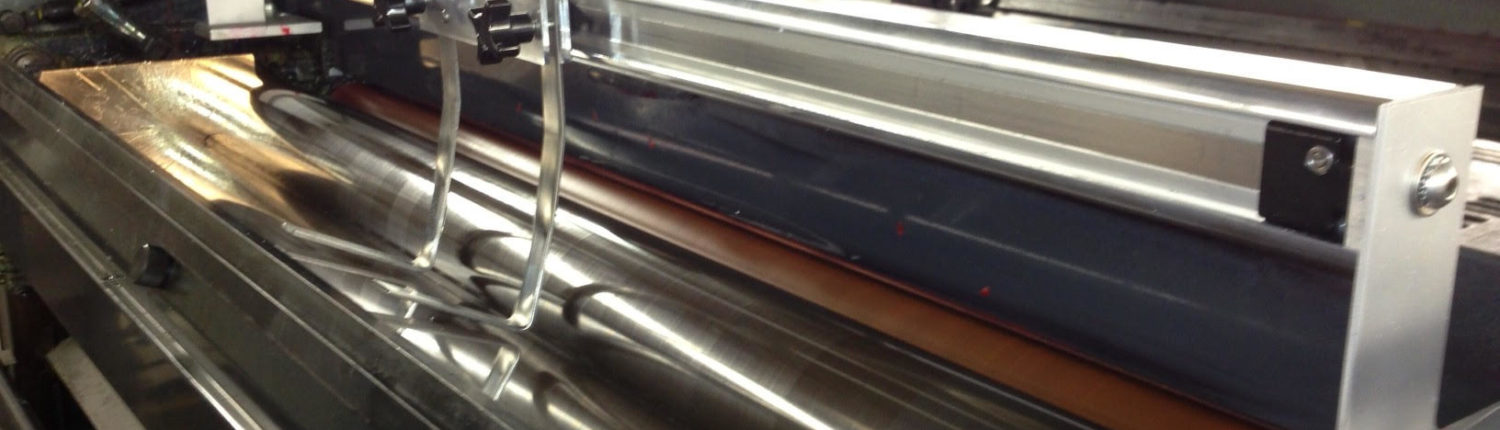

The Sajo Ink Agitator is available in either a one or two piece design and uses two stainless agitating arms that are specifically designed to not only agitate but also push ink up against the roller.

The agitating arms are stainless and are designed to be removed from the agitator bar in seconds and require no gears or rack. The most apparent advantage to this new design is the versatility of the installation enabling the bar to be positioned almost anywhere above, in front or below the fountain therefore allowing the pressman full access to the fountain at all times. The typical application for this design is with UV and conventional inks as well as metallic flex.

In addition to the versatility of bar location another significant advantage to our arm design is it’s capacity to force ink up against the fountain roller on every pass. More and more printers are having issues with ink separation from the roller and this new design completely eliminates this problem. Another advantage is the flexibility of the

stainless steel arms allowing the customer to tweak and move the arms to the desired positions as per their needs.

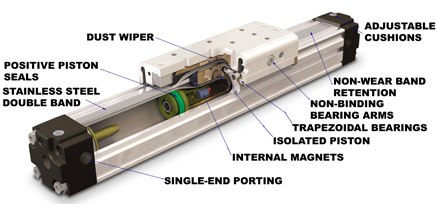

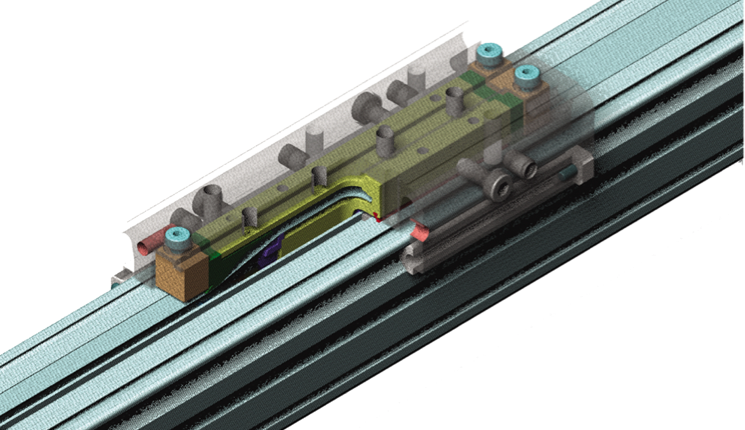

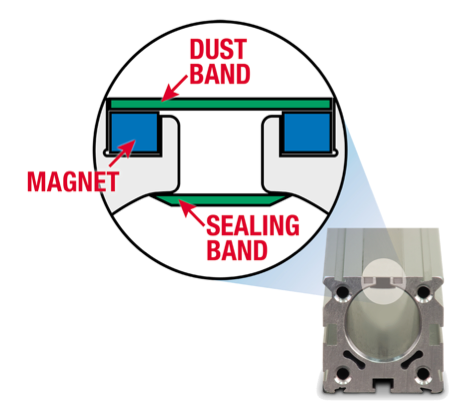

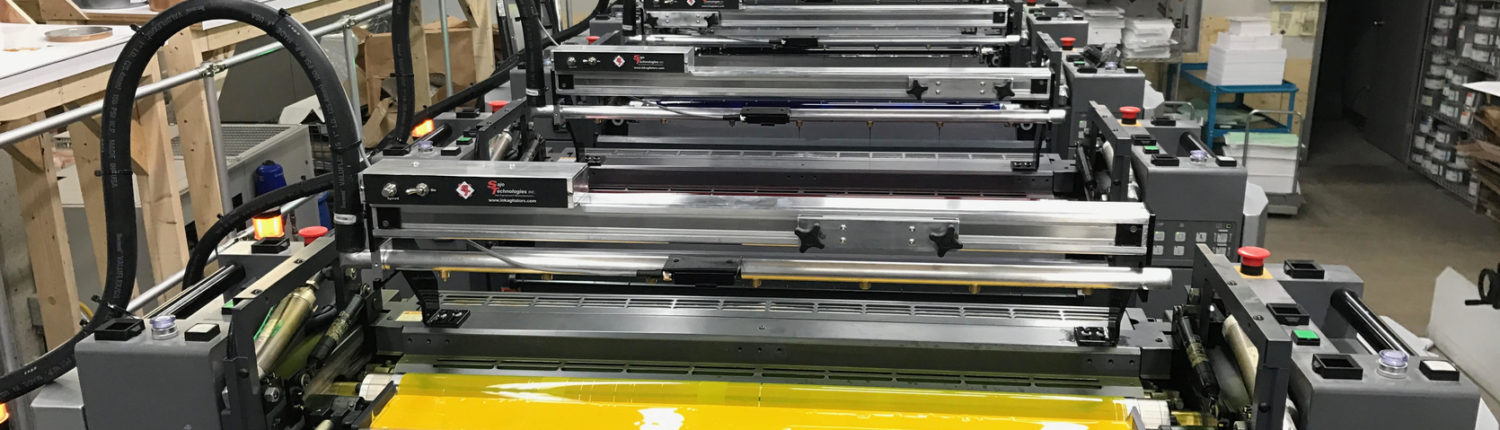

The heart of the Sajo Ink Agitator is a patented, roles double band pneumatic cylinder. The inner sealing band creates a tight metal-to-metal seal while the outer band keeps ink and dust away from the sealing band. This low profile agitator (2″ x 2″) requires no electricity, includes a speed controller and is designed with the pressman’s safety in mind. Should anything interfere with the movement of the agitating carrier bracket, it will simply reverse

direction preventing any potential accident. Agitator arms remove in seconds for easy cleaning.

Specifications

- Pneumatic double band air cylinder

- One or two piece agitator design

- Complete with On/Off switch and Speed controller

- 2″ x 2″ (5cm x 5cm) compact design cylinder that can be placed over or in front of the fountain

- No electrical required

- Control box 1.5″ x 3″ x 10″ (3.8cm x 7.6cm x 25.4cm) can be placed on either the gear or operator side of the press

- Customized mounting brackets

- Removable agitator arms for easy change out and cleaning

- Agitator arms change direction on contact and cannot stall

- Single-end porting allows convenient one end air connection

Technical Features

Air Requirements – 90 – 110 psi (6.2-7.5 bar)

Air Consumption – .4 scfm

Airline In – 1/4″ Or (6mm) push and lock

Control Box Dimensions – 1.5″ x 3″x 10″ (3.8cm x 7.6cm x 25.4cm)

Agitator Bar Dimensions – 2″ x 2″ (5cm x 5cm)